As an engineer who has integrated waste disposal systems into heavy industrial environments, I can tell you that a Four-Shaft Shredder is a different beast entirely compared to single or double-shaft machines. It is the “heavy lifter” of the shredding world.

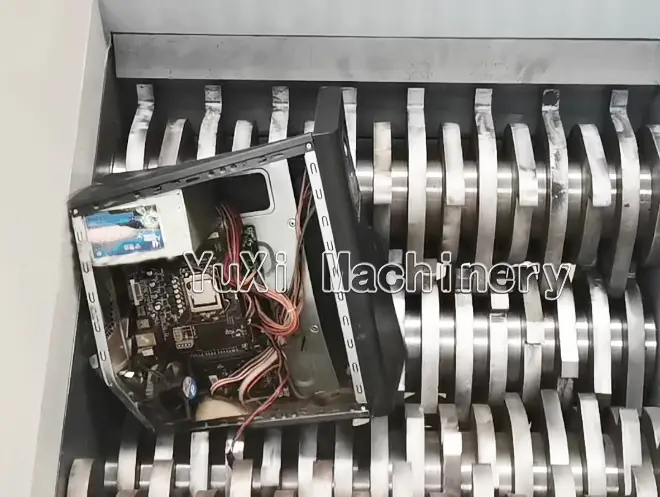

While double-shaft shredders are great for primary tearing, a four-shaft design offers superior particle size control and the ability to handle complex, bulky materials like metal drums, tires, and e-waste. Here is my professional guide to choosing the right one, based on technical parameters and factory-floor reality.

1. Evaluate the Blade Material (The SKD11 Standard)

In my experience, the blades are where most companies try to cut costs—don’t let them.

- The Engineer’s Choice: Look for SKD11 (D2 steel) blades.

- Why it matters: SKD11 offers a perfect balance of hardness and high toughness. When shredding “unpredictable” waste like household appliances or wood with nails, inferior blades will chip or crack. SKD11 maintains its edge under high-intensity impact, which means fewer shutdowns for blade sharpening.

2. Torque Over Speed: The Planetary Reducer

Beginners often focus on RPM, but pros focus on Torque.

- The Setup: A high-quality four-shaft shredder should use a Planetary Reducer.

- Practical Advantage: Compared to standard gearboxes, planetary reducers are compact but have a massive load capacity. If you are shredding metal drums or scrapped car parts with four shaft shredder, you need that “constant bite” without the motor stalling. In my projects, machines with planetary reducers have a significantly longer service life under 24/7 heavy-load conditions.

3. Precision in the Shaft and Bearings

The four-shaft configuration creates immense internal stress.

- The Core: Ensure the shaft is made of heavy-duty special steel and utilizes high-precision rolling bearings.

- Factory Tip: During a site visit, listen to the machine. A well-engineered shaft/bearing assembly runs with a deep, consistent hum. High-vibration or “clacking” sounds usually indicate poor bearing alignment, which will lead to a catastrophic shaft failure within six months of operation.

4. Automation and PLC Control (The “Brain”)

In modern waste management, you cannot afford to have an operator standing over the hopper all day.

- The Must-Have: A PLC automatic control system.

- Real-World Utility: You need a system that monitors bearing temperature and current load in real-time.

- My Experience: The most valuable feature of a PLC is the auto-reverse function. If a piece of metal is too thick, the PLC detects the current spike, reverses the shafts to reposition the material, and tries again. This prevents motor burnout and saves hours of manual labor.

Technical Selection Matrix: Common Applications

| Material Type | Key Selection Factor | Recommended Configuration |

| Metal Drums / E-Waste | High Impact Resistance | SKD11 Blades + High Torque Reducer |

| Medical Waste | Volume Reduction | Modular Box Design (for easy cleaning/sterilization) |

| Tires / Hard Plastics | Shearing Force | Interlaced Blade Pattern + Fine Mesh Screen |

| Furniture / Pallets | Multi-Dimensional Tearing | High-Speed Rotation with Reinforced Tooth Plates |

5. Maintenance: The Modular Advantage

Look for a modular box design. As an engineer, there is nothing I hate more than a machine that requires a total teardown just to replace one set of seals or inspect a shaft. A modular design allows you to access the cutting chamber and bearings quickly, reducing your Mean Time to Repair (MTTR).

Summary: The Final Verdict

If you are processing uniform, light waste, a four-shaft might be overkill. But if your feed material is bulky, mixed (wood/metal), or requires a specific output size in a single pass, the four-shaft shredder is the only professional choice.