Four-shaft shredder is a solid waste disposal equipment that adopts a structure of four sets of shearing knife rollers. It is mainly used for processing materials such as metal drums, used tires, hard plastics and scrapped household appliances.

Application

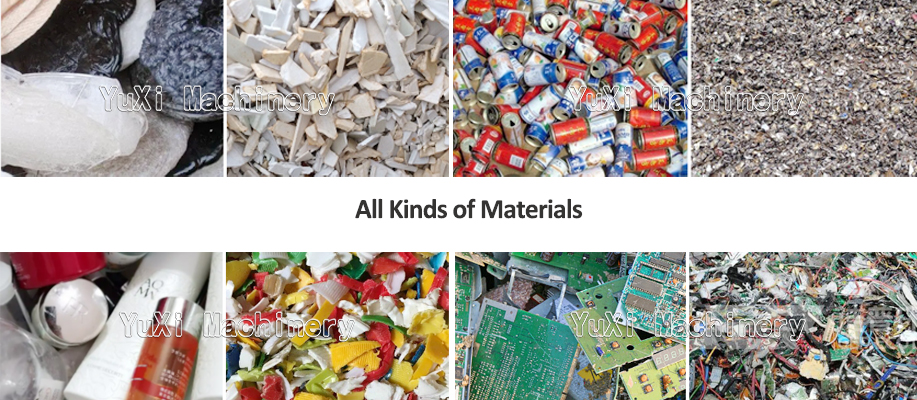

Industrial waste treatment: It processes industrial waste such as scrapped steel plates, large color steel tiles, and used cars. After shredding, it is convenient for transportation and recycling.

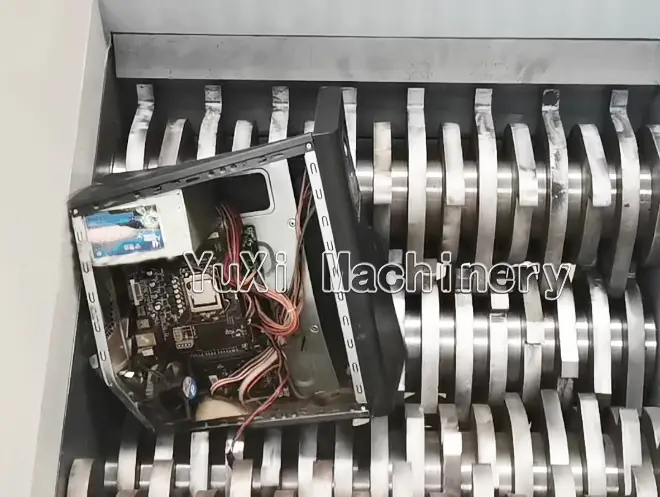

Electronic waste recycling: Crushing used household appliances, circuit boards and other electronic materials to assist in subsequent disassembly work.

Medical waste: Shred medical waste to reduce its volume and facilitate safe disposal.

Wood/metal mixed materials : Crush large items such as wooden furniture and pallets to enhance recycling efficiency.

Working Principle

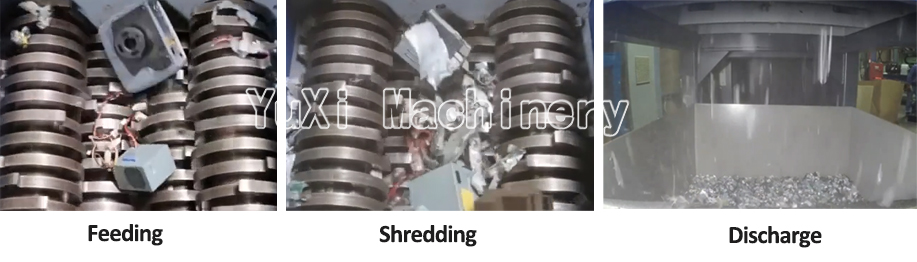

The core working principle of a four-shaft shredder is based on the coordinated operation of four high-speed rotating shafts. All four shafts are equipped with carefully designed blades, and the blades on adjacent shafts are arranged in an interlaced pattern. After the equipment is started, the motor drives the four shafts to rotate synchronously at high speed. Once the material enters the shredding chamber, it is immediately subjected to multiple actions by the blades. Firstly, the high-speed rotation of the blade generates a powerful shearing force, cutting the material from different directions and causing it to be torn in multiple dimensions. Meanwhile, the high-speed rotation of the shaft also generates centrifugal force, which throws the materials towards the inner wall of the shredding chamber, where they collide violently with the tooth plates on the inner wall, further promoting the crushing of the materials. Under the combined effect of various forces such as shearing, collision and rubbing, the material is gradually refined to the required size and finally discharged through the outlet at the bottom.

Feature

1.SKD11 features high toughness and crack resistance, maintaining the integrity of the blade even under high-intensity impact loads.

2.Planetary reducers operate by gear meshing, featuring small size, light weight, strong load capacity and long service life.

3.The knife shaft, which adopts high-precision rolling bearings and is processed with heavy-duty special steel, can withstand the impact force during high-load shredding operations, ensuring the stable operation of the equipment.

4.Equipped with a PLC automatic control system and modular box design, it supports real-time monitoring of operating parameters such as bearing temperature and current load.