Plastic crusher is mainly used to break down various plastic products (such as waste plastic sheets, pipes, films, etc.) into granules or powder, which can be directly used for injection molding or granulation regeneration.

Application

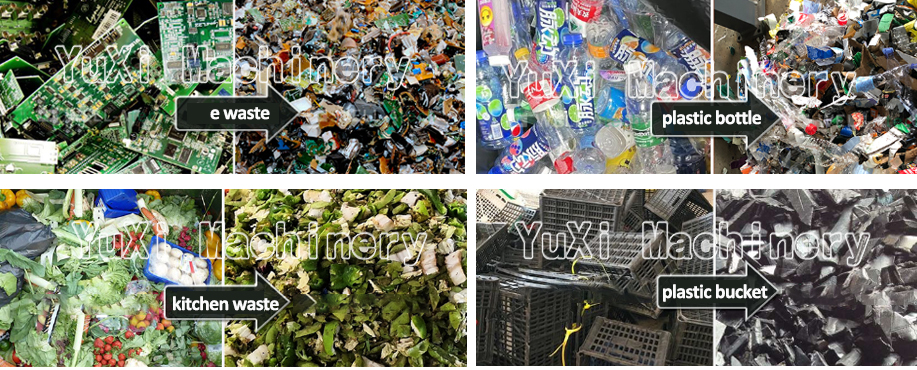

1.Recycling and Processing

It is applicable to the recycling of waste plastic products such as plastic packaging materials, pipes and films, and realizes the recycling of resources through crushing.

2.Industrial Production Assistance

During the injection molding process, the sprue material (waste generated by the injection molding machine) and defective products can be crushed and directly recycled to reduce costs.

3.Material Compatibility.

Supports crushing of various materials such as ABS, PE, PP, PVC,waste rubber products ,etc.

Working Principle

1.Feeding Stage: Plastic materials (such as scraps, spout materials, or waste products) are fed into the crushing chamber from the feeding port.

2.Crushing Stage: The motor drives the main shaft to rotate, driving the alloy steel blade to move at high speed. The moving blade and the fixed blade form relative motion, cutting plastic through shear force or breaking hard materials through hammer impact force. composite materials and filler containing plastics require high-strength cutting blades and adjustable blade clearance treatment.

3.Screening and Discharging Stage: After crushing, the particles enter the screening chamber, and the sieve screen filters out the unqualified particles (returning to secondary crushing), and the qualified particles are discharged.

Feature

1.Efficient Crushing

Adopting a sealed bearing structure to ensure long-term stable operation, the blade design is reasonable, which can achieve efficient crushing and uniform particle size.

2.Automated Operation

Some models are equipped with touch screens, which can monitor the operating status, adjust parameters, and provide fault prompts in real time; The automatic feeding system automatically adjusts the feeding amount according to the load.

3.Eco-design

Fully sealed grinding chamber, combined with air and water cooling system, reduces dust pollution; Some models adopt a fully integrated steel structure design, which is stable and durable.

4.Easy Maintenance

Most models have door covers that can be quickly opened for easy cleaning of residual materials; The operation of tool replacement and gap adjustment is simple, and the maintenance cost is low.

Parameter

| Models | YX-2640G | YX-2650G | YX-3660G | YX-3680G | YX-4680G | YX-46100G | |

| Powder | kw | 7.5 | 11 | 15 | 22 | 30 | 37 |

| Rotor Speed | rpm | 560 | 560 | 560 | 560 | 560 | 560 |

| Screen Diameter | mm | Ф10 | Ф10 | Ф12 | Ф12 | Ф12 | Ф12 |

| Cutting Chamber Size | mm | 270*400 | 270*500 | 370*600 | 370*800 | 480*800 | 480*1000 |

| Output | kg/h | 300~ 550 | 400 ~ 650 | 400~ 700 | 600 ~ 900 | 700~1200 | 800~1600 |

| Noise | dB(A) | 80~ 95 | 80~ 95 | 80~ 95 | 80~ 95 | 80~ 95 | 80~ 95 |

| Weight | kg | 550 | 650 | 1200 | 1350 | 1690 | 1850 |

| (L X W x H) Overall size | mm | 1315*960*1485 | 1315*1060*1485 | 1630*1185*1875 | 1630*1385*1875 | 1800*1430*2130 | 1800*1630*2130 |