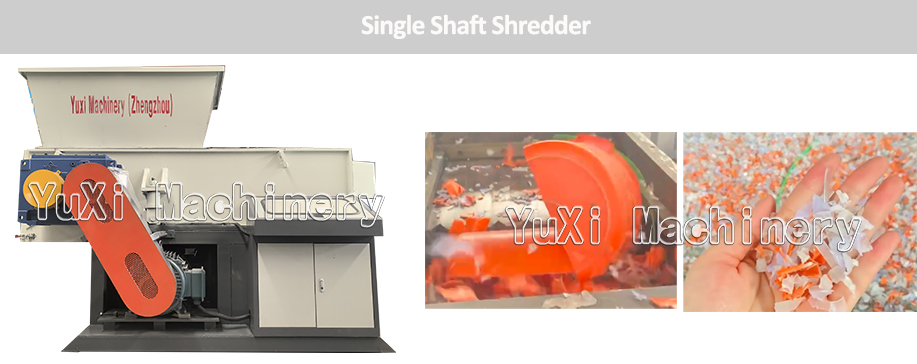

What is Single Shaft Shredder ?

Single Shaft Shredder is a solid waste crushing equipment specially designed for handling entangled materials, and is widely used in the material recycling of industries such as plastics, wood, rubber, metals, electronic waste, and waste paper.

Single Shaft Shredder Video

Application

1.Industrial Waste Treatment

It is applicable to materials such as plastic sheets, pipes, films, and waste tires. It can shred large pieces of waste plastic into small ones, facilitating subsequent crushing, granulation, and resource recycling.

2.Domestic Waste Treatment

It is used to handle large pieces of waste (such as discarded furniture and branches) and organic waste (such as vegetable residues), accelerating the composting decomposition speed and enhancing the resource utilization rate.

3.Electronic Waste Disposal

It can shred complex materials such as circuit boards and metal casings, facilitating subsequent disassembly and recycling of precious metals and harmful substances, and reducing environmental pollution.

Working Principle

After the materials enter the box through the feeding system, the hydraulic pushing device pushes them to the blade area to ensure stable force application. The reduction motor drives the main shaft of the blade to rotate. The moving knife and the fixed knife work together to apply tearing, squeezing and shearing to the material, breaking it into small pieces. The small pieces of crushed materials are discharged through a custom-made screen

Feature

1.The moving knife adopts DC53 material, and the hardness reaches HRC60 ± 1,The fixed knife is made of D2 material and its hardness reaches HRC60 ± 1

2.The integral bearing housing design is adopted, and the tolerance of the center height from the main shaft is controlled within 10 microns, which improves the installation accuracy

3.The rotational speed is reduced and the torque is increased through gear meshing. The load-carrying capacity is enhanced by using hard-toothed gears, making it suitable for high-intensity operations

4.The rotational speed is usually 45 to 100 revolutions per minute. The structural design reduces the operating noise.

5. The minimum output particle size can reach 20mm, and the screen mesh diameter can be customized to meet different recycling requirements

Parameter

| Model | YX-A600 | YX-A800 | YX-A1000 | YX-A1200 |

| Biggest rotary diameter | 255mm | 255mm | 255mm | 300mm |

| Number of rotary blades | 26 | 45 | 58 | 71 |

| Speed of rotary shaft | 82rpm | 90rpm | 87rpm | 87rpm |

| Number of fixed blades | 1 | 2 | 2 | 2 |

| Hydraulic power | 2.2kw | 3kw | 5.5kw | 5.5kw |

| Working pressure | 6-12Mpa | 6-12Mpa | 6-12Mpa | 6-12Mpa |

| Capacity | 250-400kg/h | 250-450kg/h | 300-600kg/h | 500-1000kg/h |

| Feeding size | 600mm*950mm | 800mm*950mm | 1,000mm*1,000mm | 1,200mm*1,100mm |

| Power of main motor | 22kw | 37kw | 55kw | 75kw |

| Total weight | 3,500kg | 4,500kg | 6,000kg | 8,000kg |

| External dimension | 3000*1600*2000mm | 3300*1800*2400mm | 3850*2000*2700mm | 4000*2200*2800mm |

| Maximum yield | 650kg/h | 900kg/h | 1000kg/h | 1200kg/h |