What is Scrap Metal Recycling Line ?

The scrap metal recycling line is a specialized production line used to process metal waste such as scrapped cars, household appliances, and lightweight scrap steel, achieving resource utilization through processes such as crushing and sorting.

Scrap Metal Recycling Line Video

Application

1.Car Dismantling

Processing scrap aluminum alloy waste such as car body frames and engine components, removing accessories such as tires and glass through pre-treatment, and using a crushing and sorting system to separate aluminum from impurities such as steel and plastic, with a recovery rate of up to 95%.

2.Construction Waste Recycling

By crushing waste aluminum profiles such as doors, windows, and curtain wall materials, and separating aluminum from insulation strips, the aluminum recovery rate can be increased to over 98%. At the same time, materials such as steel bars and iron pipes generated from building demolition can be processed.

3.Home Appliance Recycling

Crushing the shells and internal metal structural components of household appliances such as refrigerators and air conditioners, extracting aluminum particles with a purity of 99%, and recycling plastic shells and copper wires. Each ton of aluminum containing waste can produce 850kg of high-purity aluminum.

4.Industrial Metal Recycling

Processing waste metal products such as industrial equipment and mechanical parts, achieving efficient separation of melted raw materials through crushing, and reducing smelting costs.

5.Electronic Waste Disposal

Recycling metal resources from precision components such as laptops and mobile phone motherboards, the new generation of equipment can increase sorting efficiency by 40%, achieving refined recycling of metals such as copper and aluminum.

Working Process

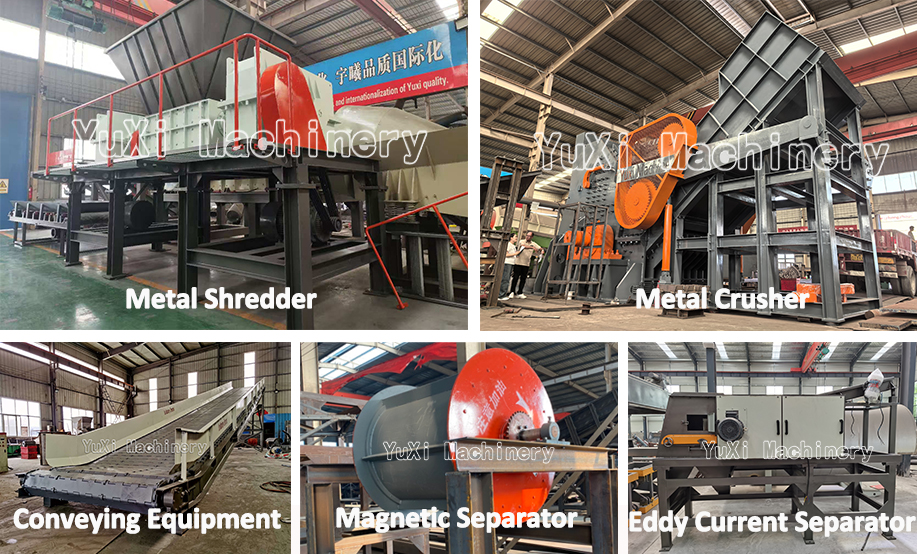

1.Metal Shredder:Metal materials enter the interior of the shredder box through the feeding system.The material is continuously sheared, squeezed, and torn by blades inside the box, and is broken into small pieces. The crushed material is discharged through sieve holes at the bottom of the box, and the size of the sieve holes can be adjusted according to demand to control the particle size.

2.Metal Crusher:The scrap metal crusher is based on the principle of hammering, which uses a high-speed motor to drive the hammer head on the rotor to strike the scrap metal entering the chamber. Under the action of impact and friction, it tears and squeezes it into granular or block materials.

3.Magnetic Separator:Based on the principle of electromagnetic induction and magnetic sorting technology, it is mainly used to separate ferromagnetic substances (such as scrap steel) from non-magnetic substances (such as non-ferrous metals, plastics, etc.) in scrap metal.

4.Eddy Current Separator:By using an alternating magnetic field to induce eddy currents inside non-ferrous metals, and utilizing electromagnetic repulsion to separate non-ferrous metals such as copper and aluminum from mixed materials.

5.Conveying Equipment:Chain conveyor combined with tape and steel plate welding structure can achieve large angle material transportation

6.Vibrating Screen:The vibration motor drives the sieve box to undergo high-frequency vibration.Materials of different particle sizes are separated due to differences in inertia and friction forces.

Feature

1.Efficient automated production

Adopting a streamlined design, it integrates functions such as crushing, sorting, and dust removal, achieving full process automation control. The PLC system can monitor the real-time operation status of equipment, automatically adjust load balance, reduce manual intervention, and improve overall production efficiency.

2.Environmental Protection and Safety

Equipped with a dust removal system (cyclone+bag filter), it effectively adsorbs fine dust particles and meets environmental standards. Some equipment is also equipped with noise reduction devices to reduce working noise.

3.Intelligence and Adaptability

Supports 24-hour continuous operation and can adjust process parameters according to different materials such as scrapped cars, household appliances, circuit boards, etc. For example, circuit board breakage lines can handle electronic waste containing heavy metals, achieving resource recycling and pollution control.

4.Improve Recycling Efficiency Optimize equipment load distribution and reduce energy consumption through intelligent control systems. For example, the crushing and sorting efficiency of the scrap aluminum production line can reach several times that of traditional single equipment, and the recovery rate is significantly improved.